Battery manufacturer Midac has extended its forklift battery range to include explosion proof batteries with the help of Pyroban’s Ex-Solutions Consulting team.

“Midac is a well-known forklift battery brand that did not have any explosion proof options available and was missing potential business opportunities in hazardous areas,” says Neil Elliot, Certification and Compliance Engineer for safety company Pyroban® which provides explosion proof solutions across a range of sectors.

“With Pyroban’s expertise, we helped Midac bring a complete Ex range of batteries to market quickly and in the most cost-effective way,” he says. “It’s our job to help customers win business in hazardous area applications by helping them solve their Ex certification requirements, whether it’s a one-off project or the complete development of an Ex certified version of their product.”

The new range from Midac demonstrates that battery OEMs are acknowledging that forklift batteries need to be properly Ex certified for use in potentially explosive atmospheres. It is not possible to just “risk assess” a standard battery for ATEX operations.

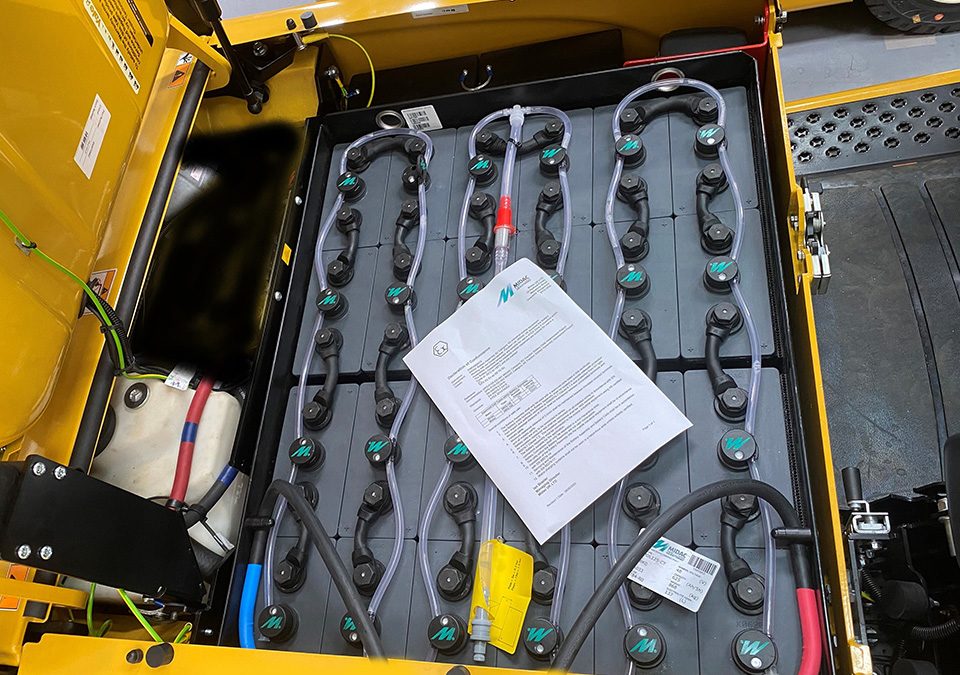

Midac places its new Ex certified battery assemblies on the market with the full Ex marking, certification, and user documentation required for ATEX. The battery assembly ranges covered include the Midac MDL, MBS Lead-acid battery type, and the PzV gel type battery. Each range comprises various individual cells that can be configured into a vast array of configurations to cover different capacity/voltage ratings.

“We have had teams from both companies working in collaboration to achieve the certification of the Midac products to the ATEX standard,” says Andy Duffield, National Account Manager for Midac who is based in Shropshire, UK. “The process has been very smooth and both companies have been very proactive in their approach to achieve a common goal.”

Midac understood that the control of the complete manufacturing process, from cell production to final assembly, was critical to the Ex certification. The company wanted to ensure that all aspects were addressed to provide a robust, safe, and ATEX compliant product for use in potentially explosive atmospheres. Pyroban combined its extensive knowledge and in-house capabilities with third-party testing to assess the battery assemblies under the Ex e and Ex t principles.

Pyroban supported the complete Ex certification process including Clause by Clause assessment, testing, production control requirements, quality records, labelling, training, change control, and documentation, resulting in a complete Midac Ex battery range for use in ATEX Zone 2 and 22 applications.

With Pyroban’s deep understanding of Ex requirements, Midac has a market-leading battery solution for dust and powder applications, where higher Ah capacity can be achieved. This increases the operating time between charges compared to other Ex battery brands, a USP which would not have been identified without Pyroban’s input.

“With positive market demand and the confidence of this successful project, we are looking to extend the range even further to include our MHE opportunity charging range of batteries and chargers,” says Andy. “This will remove the need to employ battery change in some applications.”

Pyroban remains on hand to support ongoing design changes and opportunities to further expand the portfolio. This project shows Pyroban’s capability to support manufacturers in the complex ATEX certification process, and to deliver products on time and on budget through its Ex-Solutions Consulting business.

Pyroban is based in West Sussex in the UK and is well known globally for the ATEX conversion of forklift trucks, and engine kits and packages for oil and gas applications.

“Midac is the only company that produces automotive, motive power, and stationary batteries in the same manufacturing plant, which is close to Verona in Italy,” says Andy. “In less than 25 years we have become one of the leading battery companies in Europe with products sold worldwide.”

For more information visit https://www.pyroban.com/products/ex-solutions-consulting, email sales@pyroban.com or call +44 (0) 1273 456825.