The EXSolutions team provides a range of hazardous area services directly to businesses operating with hazardous areas. Richard Ellis is one of the specialists (pictured) and has compiled some of the most frequently asked questions from businesses in the UK, across Europe and the rest of the world.

What is hazardous area classification?

Hazardous Area Classifications (HAC) are for businesses that handle dangerous substances. They include detailed calculations that consider substance and process information such as ventilation, evaporation/concentration rate, release rate, temperature and more to determine the size and specific type of ‘Zone’. This could be Zones 0, 1 or 2 in the case of flammable gas or liquids (vapour) or Zones 20, 21 and 22 in the case of powders and dusts. It could be a combination of both or classified as a “Safe” area.

Do I need hazardous area classification?

If you employ people and store, handle or process flammable or combustible material onsite then a hazardous area classification needs to be completed as part of your overall risk assessment, as an employer.

Is hazardous area classification required by law?

Yes, a hazardous area classification is a legal requirement in Europe (and the UK) if you are an employer and store, handle or process flammable or combustible material. This is a fundamental requirement of EU Directive ATEX 1999/92/EC which is covered by DSEAR in the UK and known as other local laws throughout Europe and the rest of the world (which typically follow similar principles). The mandatory requirement for risk assessment is rooted in the Health and Safety at Work Act.

My site has always been a Zone 1. Why do I need to do a new hazardous area classification?

![]() Under UK law, there must be a new hazardous area assessment carried out every 5 years, or earlier if the materials or process has changed.

Under UK law, there must be a new hazardous area assessment carried out every 5 years, or earlier if the materials or process has changed.

Quite often we find that, historically, sites have been blanket classified as Zone 1. Continuing this approach can have huge cost and safety implications and is generally considered a bad idea today.

Why? Because it means the site accepts the fact that a flammable atmosphere could form at any time anywhere onsite, which is exactly what businesses should do everything they can to prevent. It also means that all equipment has to have a passive and more expensive type of explosion protection on all equipment used in those areas.

So, it is important to isolate specific problem areas as Zone 1, leaving other areas as Zone 2 or even as safe areas. The main principle of hazardous area classification is not just about classifying areas, it is about doing everything to stop flammable atmospheres from forming in the first place and then classifying the area.

How easy is it to change from Zone 1 to Zone 2?

If an operation can reduce the risk of a flammable atmosphere from being created in the first place, which could be a simple process change, then it may be possible to easily switch from Zone 1 to Zone 2 and benefit from significantly lower capital and operational costs, and improved safety.

What’s the difference between DSEAR and COMAH?

In the UK, DSEAR relates to the operation and processes, while COMAH relates to how accidents and explosions are handled which can involve drills with local fire and ambulance services.

Is DSEAR the same as ATEX?

DSEAR is the implementation of ATEX in the UK.

How much does a hazardous area classification cost?

A hazardous area consultant costs are typically based on day rate and sometimes on the overall project. Hazardous area classification consultants can charge between £800 and £1500 per day. Projects can of course vary in length and can take 2 days to 2 months depending on the size and scale of the project.

If I have flammable liquids in sealed IBCs and barrels onsite, do I need a hazardous area classification?

If I have flammable liquids in sealed IBCs and barrels onsite, do I need a hazardous area classification?

If you have any flammable liquids in sealed IBCs and barrels onsite, a hazardous area classification should be carried out. This does not automatically mean you have formally classified Zoned areas.

Many factors affect the hazardous are classification such as substance characteristics, volume, ventilation, activity and much more. In many cases a hazardous area classification may make recommendations to change processes to reduce the risk and create a “safe area”.

If I store aerosols in bulk, do I need a hazardous area classification?

Yes. Although the volume of flammable butane (typically) is relatively small in each aerosol can (deodorant, cleaning products, hair products, cosmetics etc.), the total volume when storing in bulk can be enormous.

Supermarkets, FMCG manufacturers and related 3rd party logistics companies are all required to undertake hazardous area classification in these scenarios to prevent flammable atmospheres from forming.

If I store flour or similar food powders, do I need a hazardous area classification?

Yes. Flour is considered a combustible powder and therefore any operation handling or processing flour (or similar foodstuffs) in bulk should engage with a hazardous area classification consultant. Areas will typically then be classified as Zone 20, 21 or 22.

What does ATEX Zone 0 mean in hazardous area classification?

If your site has a hazardous area that is classified as ATEX Zone 0, it means you have a “place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.” This is usually areas directly inside vessels or immediately above flammable liquids for example.

What does ATEX Zone 1 mean in hazardous area classification?

The hazardous area classification process may designate an area as ATEX Zone 1 which means you have a “place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.” This is usually process areas where mixing or blending takes place.

What does ATEX Zone 2 mean in hazardous area classification?

Your hazardous area classification consultant may classify an area as ATEX Zone 2 which means your operation is a “place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

What does ATEX Zone 20 mean in hazardous area classification?

The hazardous area classification could classify an area as ATEX Zone 20 which is a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

What does ATEX Zone 21 mean in hazardous area classification?

ATEX Zone 21 may be used to classify a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

What does ATEX Zone 22 mean in hazardous area classification?

Today, we are seeing more operations receive an ATEX Zone 22 classification which means an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Can I do a hazardous area classification myself?

A hazardous area classification should only be conducted by a competent person in relation to the understanding of handling dangerous substances. This will include understanding the relevance of the physical/chemical properties of gases, liquids and flammable mists to area classification. The concept of a zone of negligible extent (NE), ventilation and the concept of Vz based methods are just some of the principles that the individual must understand and be able to apply, among others.

For those who require a thorough understanding of the hazardous area classification process, in depth training courses are available. For example process safety engineers, electrical engineers and health and safety practitioners can be upskilled to undertake a hazardous area classification. Talk to EXSolutions about ATEX training solutions.

Is a DSEAR Assessment the same as a hazardous area classification?

A hazardous area classification usually describes the process of designating the area or site into Zones. DSEAR is a UK regulation and the hazardous area classification is just one part of the overall DSEAR assessment. Other elements of a DSEAR Risk Assessment include:

- Hazardous substances and materials

- Handling and use of dangerous substances

- Housekeeping and storage arrangements

- Operational and Emergency procedures

- Extraction and ventilation

- Equipment rating within Zoned areas

- Sources of ignition left exposed (Read about equipment conversion)

- Inspection and maintenance

- Control measures

- Management of waste substances

- Fire risk assessment and firefighting arrangements

- Operator training

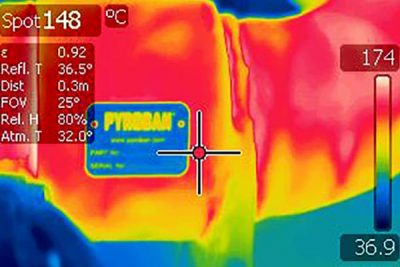

Standard products and equipment can create sparks and high temperatures with multiple other ignition sources and ignition risks. Here’s an example of the heat signature on a Pyroban protected engine which is safe for hazardous area use.

What is an ignition source?

Standard products and equipment can create sparks and high temperatures with multiple other ignition sources and ignition risks. Where explosive atmosphere exists, special precautions are required to reduce the possibility of a fire or explosion.

Electrical equipment and non-electrical equipment, mechanical equipment, must be purpose built or converted (explosion protection, explosion proof, flameproof) for use in dangerous places to prevent the ignition of a potentially explosive atmosphere.

Forklift trucks, lights, sounders, beacons, switches, engines, cranes, electrical components and most other electrical and non-electrical equipment can be purchased or converted for use in hazardous areas.

What is DSEAR?

DSEAR (Dangerous Substances and Explosive Atmospheres Regulations) is a set of UK regulations that aim to protect workers from the risks of fires, explosions, and other dangerous incidents that may occur because of the storage, handling, or use of dangerous substances in the workplace.

DSEAR assessments are required for all workplaces where dangerous substances are present.

I’ve never heard of DSEAR. How do I comply with DSEAR?

If you are handling dangerous substances onsite in the UK, then DSEAR applies to you.

You need to involve a DSEAR specialist who can look at your operation and help. You could upskill your team with training, employ a specialist or get a DSEAR consultant. Either way, if you are handling dangerous substances you may not comply and worse still, you could be putting your staff at serious risk.

Talk to EXSolutions to help you on your journey to DSEAR compliance.

What is ATEX?

ATEX refers to two European Directives.

The ATEX 1999/92/EC Directive is for industries that operate with potentially explosive atmospheres, for example a chemical company. ATEX 1999/92/EC requires companies to manage the risk and the process safely.

The ATEX 2014/34/EU Directive (previously 94/9/EC) is for industries that supply equipment into hazardous areas, for example a forklift supplier or well service equipment supplier.

How do I comply with ATEX?

If you need any support on your journey to ATEX compliance, our hazardous area classification consultants from EXSolutions can help.

Call the EXSolutions team in the UK on : +44 (0) 1273 456800 or complete the enquiry form.

If I have flammable liquids in sealed IBCs and barrels onsite, do I need a hazardous area classification?

If I have flammable liquids in sealed IBCs and barrels onsite, do I need a hazardous area classification?