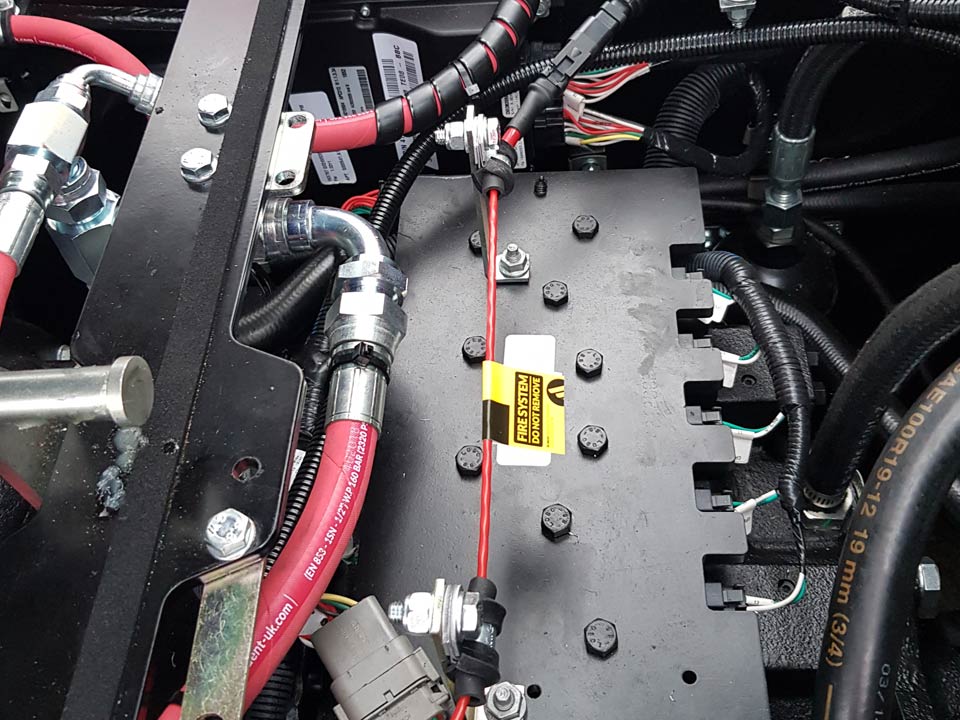

Fire Suppression Systems

Pyroban is now offering advanced fire suppression systems for a range of mobile applications helping to protect the assets, stock, premises and people. We fit automatic fire extinguishing systems to:

- Heavy Vehicles – Dry and wet chemical fire suppression systems for off-road mobile equipment.

- Light Mobile Plant – Flexible, compact fire suppression systems for forklifts, smaller plant and equipment such as MEWPs, cranes etc….

The state-of-the-Art advanced fire suppression technologies not only suppresses the fire, our systems can also prevent a new fire from starting.

The systems feature linear heat detection cable technology for reliable electronic detection and fire suppressant release. The system monitors 24/7 even when the vehicle is switched off and records events of activations and fault conditions.

Fire suppression technologies

Operators receive visual and audible notifications of system discharge or faults. The system discharge delay function allows the operator to bring the vehicle to a stop safely when working in a building or around stock piles. Events are stored with date and time stamps, allowing for analysis of systems events post-incident to help identify the cause.

For vehicle maintenance, an isolation mode also allows maintenance to be carried out without the risk of accidentally setting off the system.

For the suppression agents we recommend dual agent including dry powder (for rapid fire knock-down with excellent coverage) and a liquid agent for effective cooling.

Why cooling is important

We believe that cooling is a really important feature of a fire suppression system in mobile equipment. For example, after a system discharges and suppresses a fire, if the temperature of the turbocharger still exceeds the diesel autoignition temperature, the fire will reignite unless suitably prevented.

A turbocharger operating surface temperature is typically 500°C while the exhaust manifold operating temperature is usually between 250°C and 350°C. The turbocharger therefore needs cooling below the autoignition temperature to prevent reignition

Why use Pyroban to install your fire suppression system?

Pyroban is one of the leading companies in the world that converts equipment for use in hazardous areas (primarily ATEX areas). We therefore completely understand fire and explosion risks on mobile equipment while having strong engineering partnerships with almost all brands and types of industrial mobile equipment. Installed by CompEX accredited engineers with many year’s of experience in hazardous areas.

Pyroban’s proven experience with modification of materials handling equipment ensures high quality solutions in our 3 step process:

- Application assessment – to establish the optimum fire suppression solution

- Installation assessment – to establish the optimum detection and fire deluge nozzle positions

- Quality installation – Pyroban quality assured by our skilled technicians

Pyroban provides flexible service and maintenance packages available to suit the application.

Industries at risk of fire from mobile plant and forklifts

Several industries are at risk of fire and will benefit from fire suppression systems including:

- Mining & Quarrying

- Recycling & Waste

- Manufacturing

- Ports & Docks

- Timber and Wood Processing

- Paper, cardboard and packaging

- Construction & Tunnelling

- Agriculture – hay and straw

- Transport, storage and distribution

- Plant Hire

- Forestry

- Marine

Why use fire suppression systems on plant and forklifts?

Fires can start within the engine as a result of a fault condition or even as part of a normal operation. For example, turbo charged diesel engines run hot in normal operation and could be the ignition source. It could be that dust layers build up, smoulder and result in a fire. Typical examples are shown in the table below.