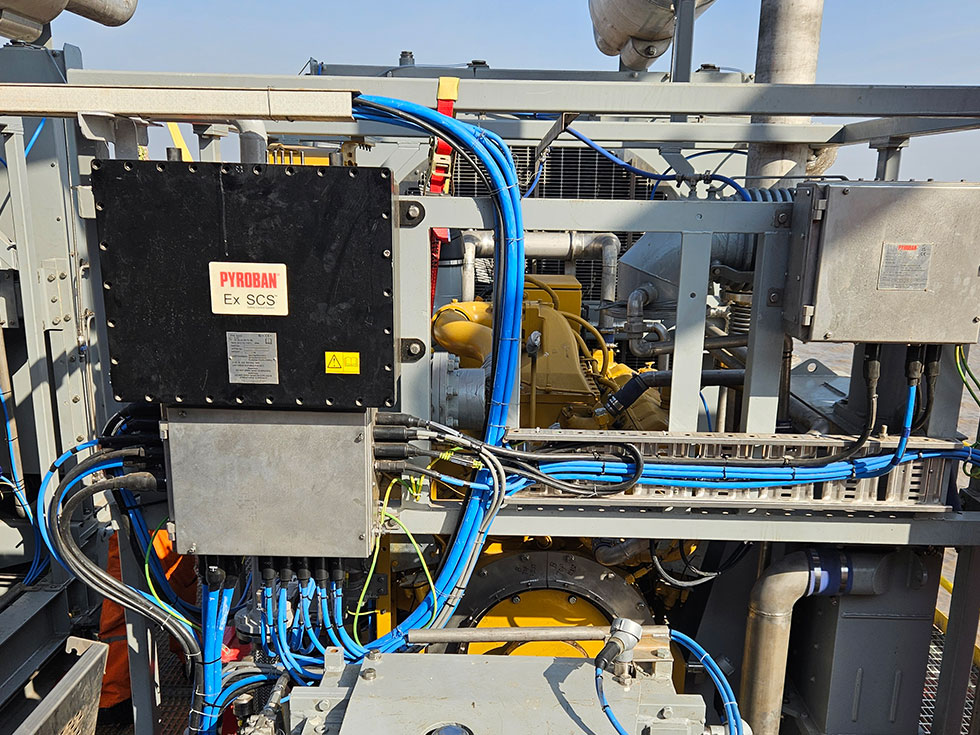

Earlier in 2024 Pyroban commissioned what is thought to be the first explosion proof natural gas internal combustion engines operating in a formally classified Zone 2 hazardous area.

As part of the global energy transition, operators are looking for ways to reduce emissions and save costs offshore.

Reduced emissions

Natural gas engines, especially those using liquefied natural gas (LNG), produce significantly lower emissions compared to diesel engines.

This includes reductions in CO2, NOx, SOx, and particulate matter, making them more environmentally friendly.

Cost efficiency of natural gas engines

Gas engines can be more cost-effective in the long run due to lower fuel costs and higher efficiency. LNG, for example, is often cheaper than diesel and can provide better fuel economy.

Photo credits: Steve Keeley from Pyroban’s offshore team

Gas engines are particularly good for unmanned operations where they can be fuelled from produced gas from the well which would otherwise be flared off.

Explosion proof LNG gas engines offshore

Pyroban was selected due to its strong reputation and rich 50+ year history in converting diesel engines for the offshore industry.

Photo credits: Steve Keeley from Pyroban’s offshore team

The gas engines’ ignition hazards were carefully assessed and using our flameproof inlet and exhaust systems, Ex SCS™ gas detection and coating technologies for hot surfaces a Zone 2, Gas Group IIA, Temperature Class T3 solution was achieved.

We are experiencing an upward trend in enquiries for explosion proof natural gas engines working in hazardous areas and expect this to continue.

More information will follow on explosion proof natural gas engines in 2025.

Contact us to discuss your Zone 2 hazardous area gas engine requirements further where our expert sales team can support you.

Photo credits: Steve Keeley from Pyroban’s offshore team