We have recently supplied an explosion proof Caterpillar 3406 Pyroban Kit for local installation at PETROGEAR in the United Arab Emirates. The explosion proof engine kit has been used as part of a Zone 2 diesel hydraulic power unit (HPU) for a hydraulic workover rig.

Pyroban kits are explosion proof safety kits for diesel engines and in this project benefit from the addition of Ever Clear™, a long-life exhaust flame arrestor that significantly reduces maintenance. The new ATEX Zone 2 powerpack will be used offshore in the Middle East and is built in accordance with ATEX 2014/34/EU and all necessary standards including EN1834-1:2000.

What are Ever Clear exhaust flame arrestors?

Ever Clear exhaust flame arrestors act as a direct replacement for the traditional “plate type” flame arrestors found in traditional Pyroban explosion protected kits. Ever Clear™ exhaust flame arrestors offer many benefits to operators, including reduced maintenance costs, increased personnel safety and reduced operational downtime.

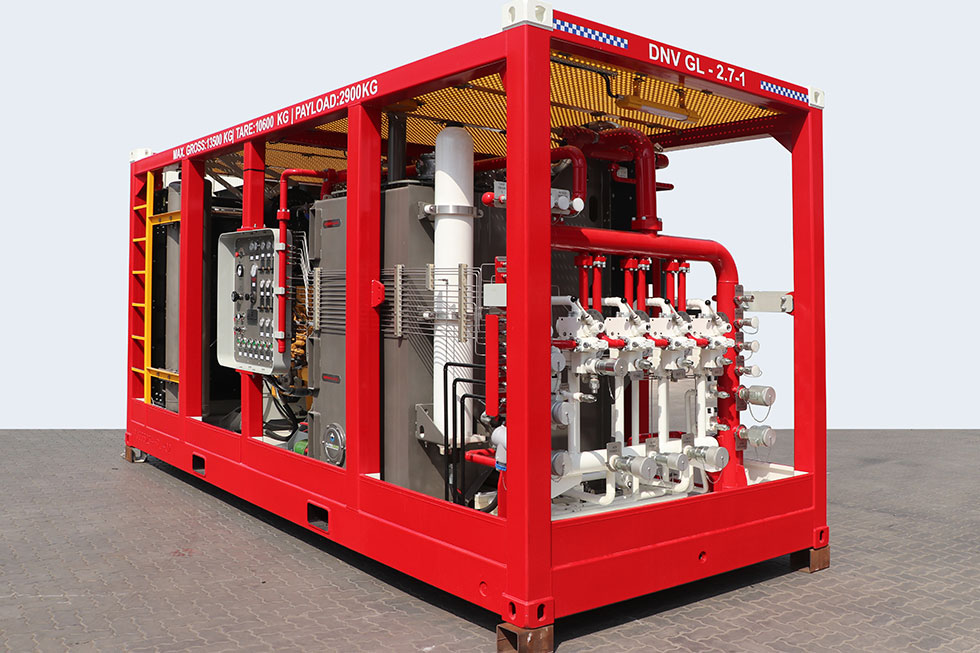

Ever Clear can be seen in the bottom centre of the picture.

As part of the Pyroban Kit, the new ATEX Zone 2 engine also features an air inlet shut-off valve, air inlet flame arrestor, water-cooled turbocharger and exhaust manifold, exhaust gas heat exchanger, thermal control and treatment and ATEX certified spark arrestor – as seen above.

Lewis Cleary from Pyroban’s specialist EX Power Systems team states: “The hot climate in the middle east is always extra challenging for ATEX Zone 2 powerpack packages, and on this occasion the engine had to stay within T3 limits in an ambient specified to 50 Deg C.”

“To achieve these temperature targets, Pyroban applied its extensive knowledge of the Caterpillar 3406 engine and strategically applied SCTB (Soft compound thermal barrier) to target the hot charge air system which will start to exceed T3 (200 Deg C) temperature class in ambient temperatures as low as 30 Deg C,” says Lewis.

Pyroban’s unique SCTB (Soft Compound Thermal Barrier) is a special black coating applied to the turbo and the charge air system. The Soft Compound Thermal Barrier ensures the engines’ charge air system components remain below temperature class T3 (200degC) at high load in a 50degC ambient environment (as specified).

Pyroban is one of the only manufacturers that provides this level of thermal control with its SCTB coating technology to reduce the thermal signature.

“Dubai based Pyroban partner Auto Craft Trading was on hand for commissioning and completion of the final SCTB on the charge air system joints and bolts, to ensure that the final thermal test by a third party notified body was a success,” says Lewis.

”With the Zone 2 engine working at full load it stayed below temperature class T3 at the target ambient,” he says. “Pyroban’s commitment to safety in hazardous areas is paramount and we achieved an excellent final result due to the collaborative efforts of all involved.”

For more information or to discuss any well service projects, please contact Lewis Cleary on +44 (0) 1273 456800 or at info@pyroban.com or connect with Lewis on LinkedIn.

Pyroban at ADIPEC

Lewis Cleary will be at ADIPEC representing Pyroban on the Pioneer Safety Group stand, Hall 8, stand 8538 4-7 November in Abu Dhabi. As part of the Pioneer Safety Group®, the team at Pyroban will be exhibiting alongside a range of other explosion proof products and hazardous area services including Ex lighting, signalling, electrical enclosures, instrumentation, materials handling solutions, engineering and hazardous areas consulting services.

Follow other Pioneer Safety Group brands Petrel®, Ex-tech Signalling®, Ex-tech Solution®, Pyropress® and EXSolutions®.