Oil & Gas Explosion Protection

The risk of fire and explosion exists in oil and gas operations throughout the value stream. The science of explosions is well understood and is the same all around the world. In these challenging times it is critical that we don’t waste these precious resources. Pyroban provides a range of explosion protection products and services to help manage the risk and remove the sources of ignition found in diesel engines and mobile equipment in offshore oil and gas installations and onshore refineries and petrochemical plants.

Our heritage stretches back 50 years and our Ex engineering capability has continuously evolved from mechanical to electromechanical to firmware on to software and PLC programming in order to support complex major projects and find development pathways to new solutions that the oil and gas industry demands. Our class leading Ex SCS system and Everclear flame arrestor technology address industry problems and lower operating costs for our customers without compromising safety or ease of operation.

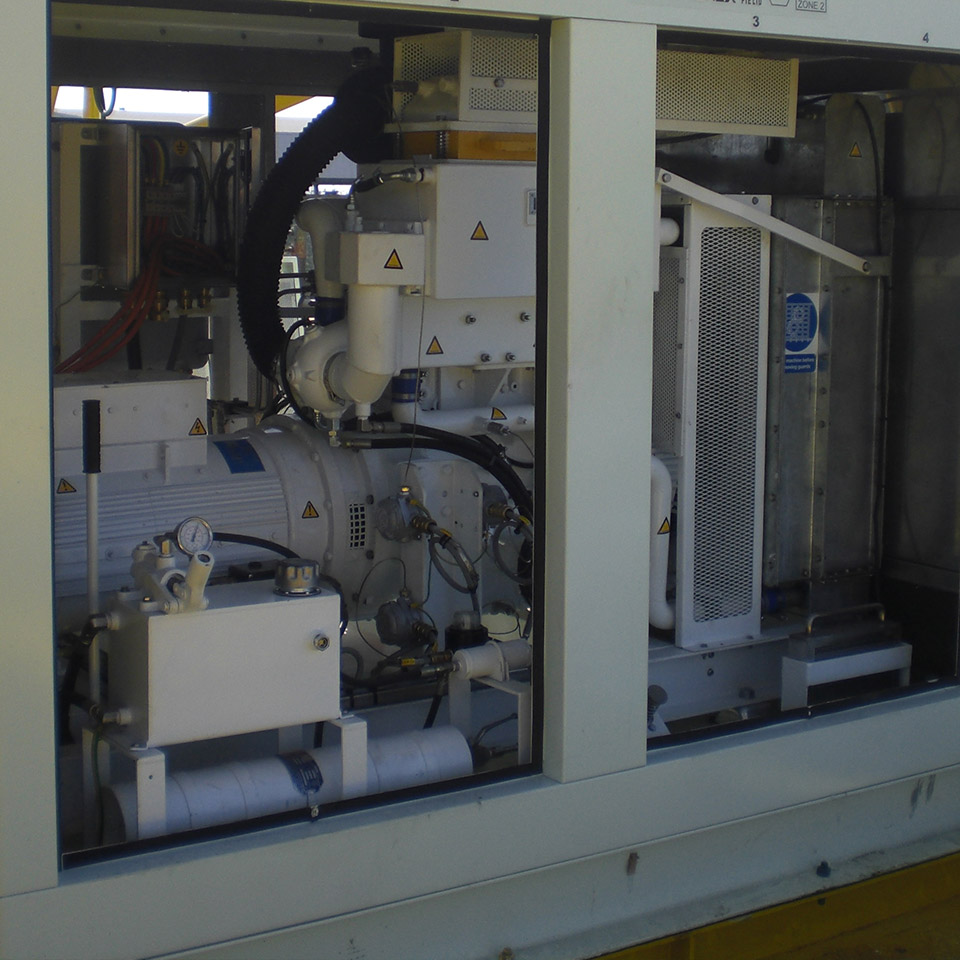

Diesel engine explosion protection

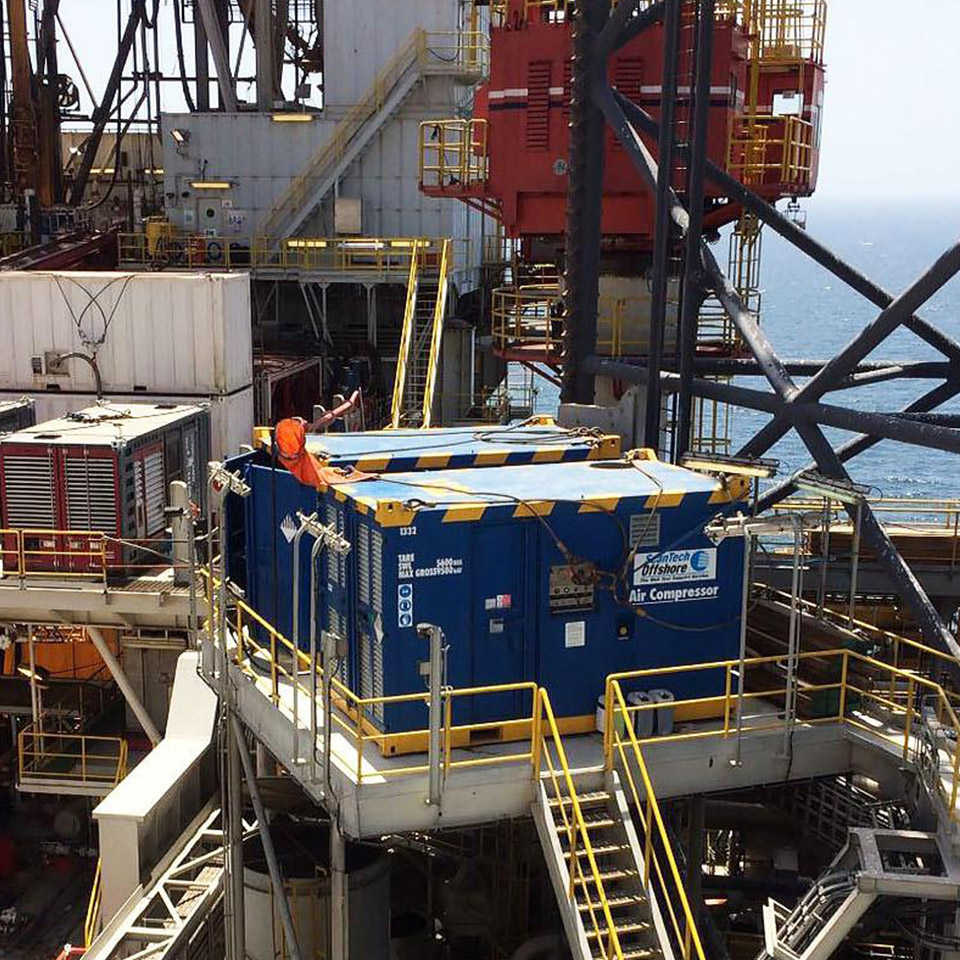

Diesel engines are used in Zone 2 areas offshore to power temporary well service equipment such as coiled tubing units, cementing units, fabric maintenance, water jetting pumps and air compressors and in production environments for firefighting pumps, emergency and essential generators. Pyroban provides:

- Explosion protection (ATEX) engine Kits – for multiple engine types used in well service equipment

- Explosion protection (ATEX) engine Packages – from leading OEMs for use in well service equipment

- Explosion protection components – Shut-off valves, spark arrestors, batteries, starter motors, control systems and more

Mobile equipment explosion protection

Lift trucks, mobile cranes and access platforms are used in Zone 2 areas offshore and also in Zone 1 and 2 areas in onshore refineries and plants, often where hard to reach maintenance and component exchange needs to take place. Pyroban provides:

- Materials handling equipment conversions for operation in Zone 1 or 2 areas – Lift trucks, pallet trucks, reach trucks and more

- Plant equipment conversions for operation in Zone 1 or 2 areas – access platforms, scissor lifts, cranes and more

- Personnel buggies

- Pick-up trucks and maintenance vehicles

Other explosion protection solutions

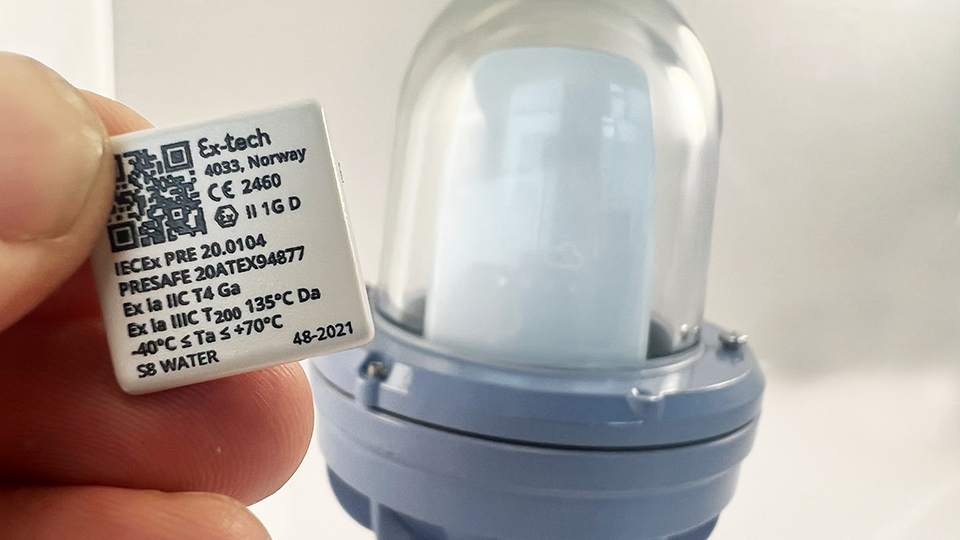

Pyroban’s new explosion protection services, EXSolutions, supports OEM and end-user businesses on their journey to ATEX, UKEX and IECEx compliance. Services include:

- Ignition Hazard Assessments (IHA), inspections, audits, and practical Ex engineering solutions for all types of equipment.

- Ex telemetry. Unique sensors to improve preventative maintenance of electro-mechanical equipment and lighting systems.

- EX electrical and mechanical system design, EX enclosure population, EX product development and certification support for OEMs. Find out more

- Ex lighting design and installation services providing energy efficient LED lighting solutions.

- Advanced fire suppression systems for a range of mobile and fixed equipment applications (not Ex).

Oil & Gas

Oil & Gas Cosmetics & Pharma

Cosmetics & Pharma Chemicals, coatings & inks

Chemicals, coatings & inks Food, Drink & Distilleries

Food, Drink & Distilleries Logistics

Logistics Waste

Waste Military

Military Other

Other